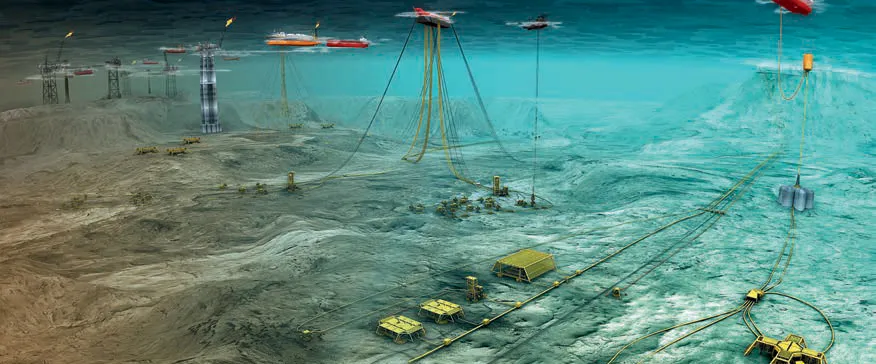

Early involvement of equipment suppliers and focus on standardisation and integrated contracts is the way to go for the vast majority of subsea developments – also on the NCS, according to Rasmus Sunde. Illustration: Forsys Subsea JOINING FORCES – CUTTING COSTSBy optimising subsea architecture and executing the projects together, Technip and FMC Technologies aim to deliver subsea solutions at a cost that is around 30 per cent cheaper than they can manage working separately. This could make the difference between whether or not a discovery is developed. | |||

Costs per subsea well have tripled over the last ten years, while delivery time has doubled. These trends have been driven in part by more complex reservoirs and challenges such as high pressure and high temperatures, but also by the industry's failure to implement standardisation. This was the background for Technip and FMC Technologies' decision to sit down together in 2014. This was not a sustainable development, even with much higher oil prices than we are seeing today. In combination, the two companies account for around 30 per cent of the costs associated with a typical subsea development. Pooling resources, technology and expertise would give the companies an opportunity to realise substantial savings. Forsys Subsea first saw the light of day on 1 June 2015. Overnight, everyone who worked on conceptual studies and preliminary engineering (FEED) in the parent companies, was transferred to the joint venture. This was also the case for the groups working on monitoring and verification of data, as well as decision support systems and consultancy for operators. | EARLIER INVOLVEMENT IN THE PROCESS Today, the company has 320 employees, and is led by Rasmus Sunde. He is convinced that early involvement by the equipment suppliers and focus on standardisation and integrated contracts is the way to go for the vast majority of subsea developments – also on the Norwegian Shelf. "When you are looking for tailored design and special solutions, both at the operator level and the field level, you normally have to sacrifice economies of scale. We spend way too many engineer hours on relatively simple tasks," says Sunde. The key is to get into the process at an earlier point in time, before the oil companies have made all the design and materials decisions. Then you can avoid spending money on more expensive solutions that aren't strictly necessary. There's been too much of that in the past, he says. Plus, there are significant savings when it comes to implementation time. "Nobody knows our products better than we do. A subsea Xmas tree is made up of 7000-8000 components. You can just imagine the expense if others are going to choose materials way down in our supplier chain, compared with the economies of scale we achieve when we use a standard we developed ourselves, says Sunde | BEST OF TWO WORLDS Technip and FMC Technologies are not the only ones thinking along these lines. In 2015, GE and McDermott joined to create IO Oil & Gas Consulting, Aker Solutions has instituted subsea cooperation with Saipem, and OneSubsea has signed a global alliance with Subsea 7. Sunde believes that this allows oil companies to have the best of two worlds. First, they can announce design competitions to find the best solution. Then they convert this at a fixed price. Introducing competition at an earlier stage of the process means that they can achieve both better and more cost-effective design, the market's best price, and safer project execution. "It all seems so easy, but back when oil prices were high, the industry was most concerned with boosting production. After 30 years in the industry, I have seen that the greatest creativity comes during the biggest crises, both in terms of technology and business models," says Sunde. FIRST CONTRACT EXPECTED IN 2016 Forsys Subsea is working to identify simplifications and cost savings on subsea projects that have been shelved due to global high prices. A large number of projects are being assessed at any given time, also on the NCS, says Sunde, who expects to land the first integrated implementation contract during the course of the year. | "We must investigate every opportunity to bring down the cost level. New operating models are one of the alternatives. Forsys is a supplier that seeks further development in this direction." |

"After 30 years in the industry, I have seen that the greatest creativity comes during the biggest crises, both in terms of technology and business models." Rasmus Sunde |  Photo: Forsys Subsea Forsys Subsea

| Giants merge – Technip and FMC TechnologiesOn 19 May, Technip and FMC Technologies announced that the companies would merge. The new company's operating revenues in 2015 were around USD 20 billion. The merger is expected to trigger cost savings of USD 400 million in 2019. "Forsys Subsea was a micro-merger in comparison, yet it did give the parent companies a taste of what we can achieve," says Rasmus Sunde. | |